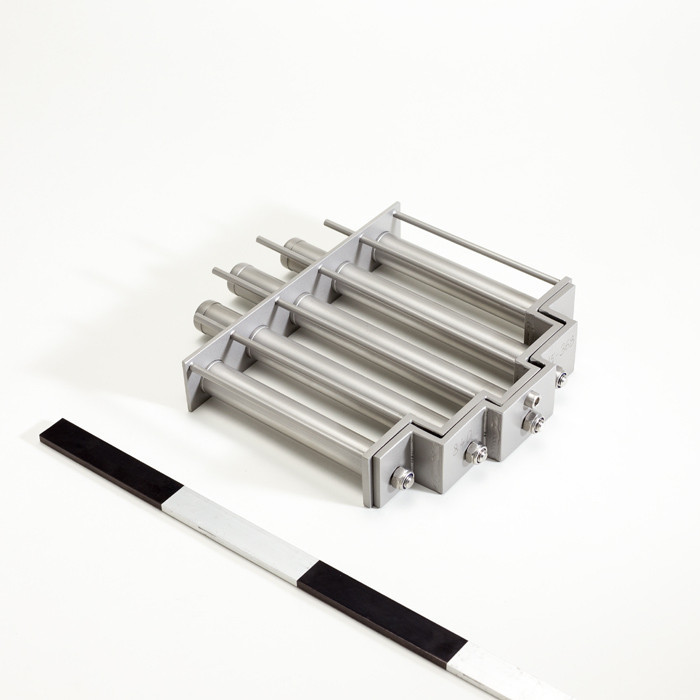

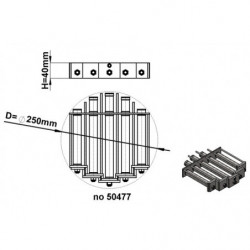

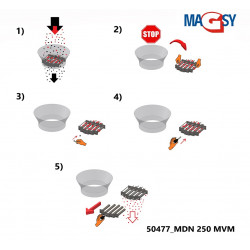

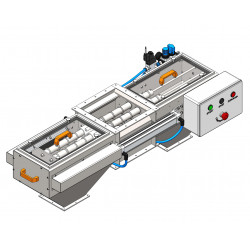

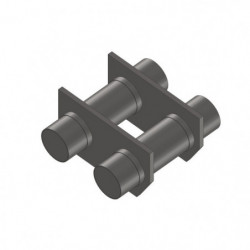

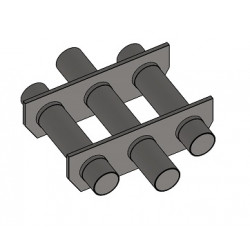

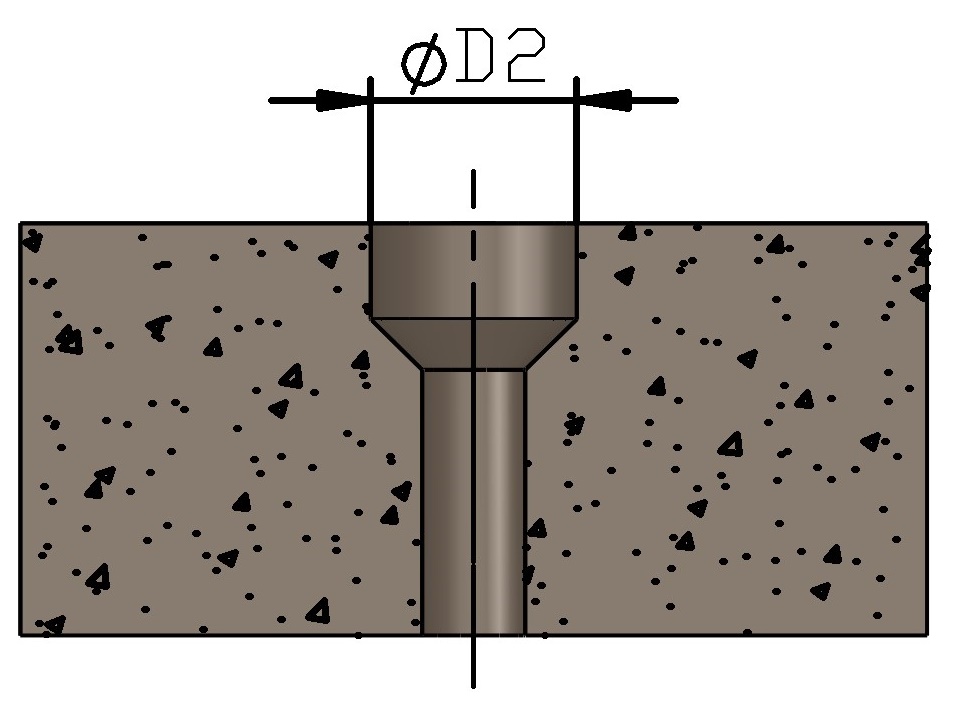

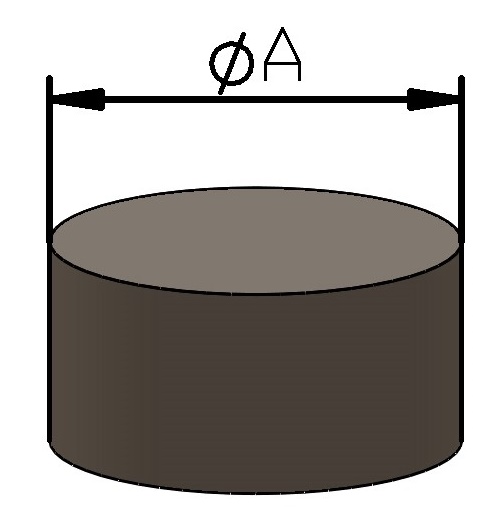

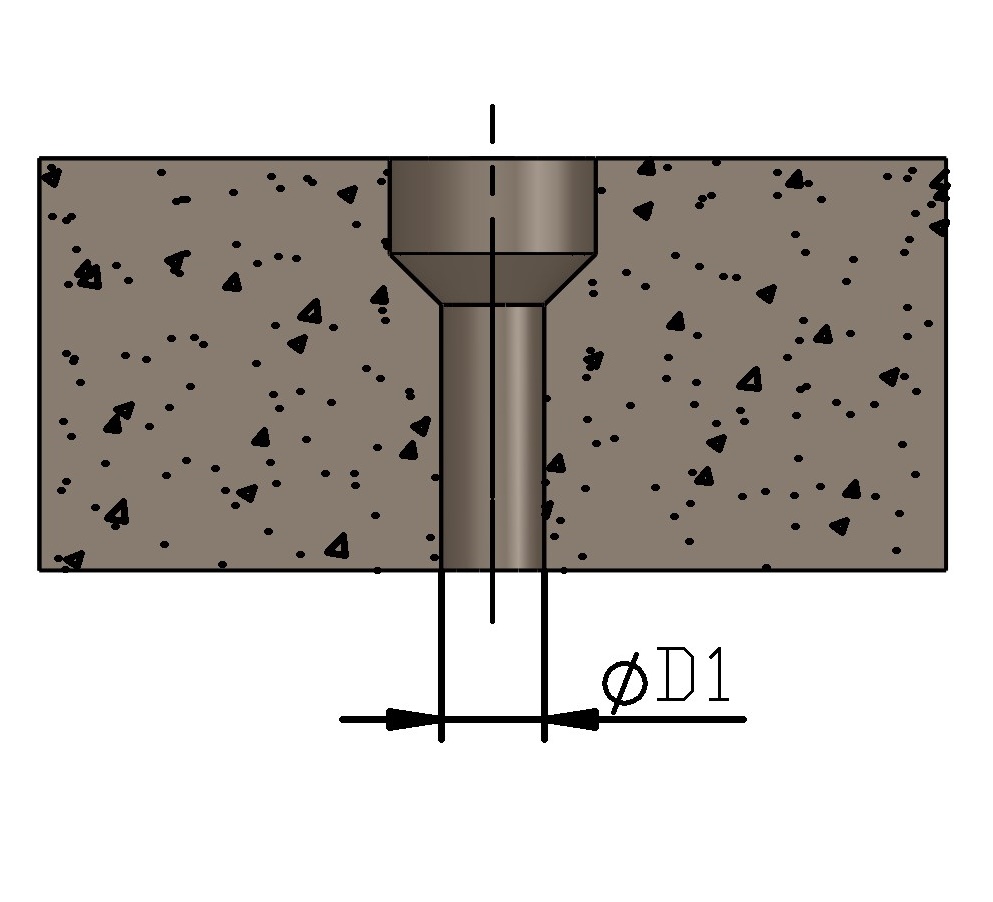

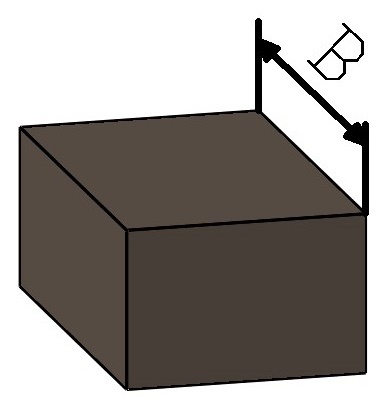

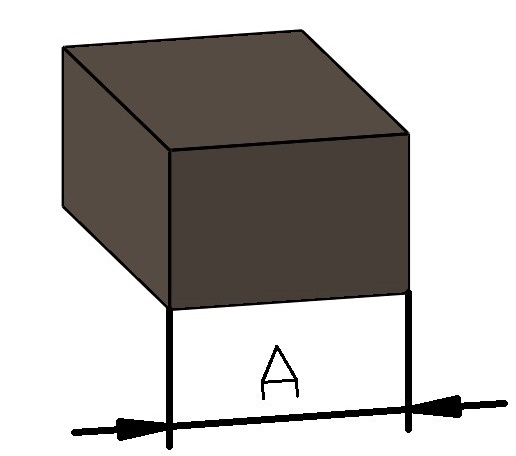

Magnet for injection moulding machine hopper (temperature resistance up to 120 °C) dia. 300 mm

50498

In Stock

We'll send on Monday

Price

€1,119.91Tax excluded

Magnet for injection moulding machine hopper (temperature resistance up to 120 °C) dia. 300 mm

50498

In Stock

We'll send on Monday

Price

€1,119.91Tax excluded